Ewellix provides effective solutions to complete vertical and horizontal adjustment in a smart way with a wide range of “ready to mount” additional linear axis solutions.

We designed them for different applications, giving your robot an extended operational range.

LIFKIT

- Load up to 1,5 kN

- Speed up to 80 mm/s

- Stroke up to 1 400 mm

- Plug and play with Universal Robots, Omron TM, Techman TM, ANUC cobot…

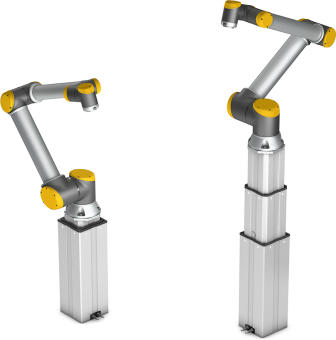

Robots are often used for palletising, material handling, inspection, construction, etc., but reach their limits once the robot arm is fully extended at a certain height.

The easy-to-assemble LIFTKIT increases the reach of the robot by moving it along a vertical axis. The base of the robot can be raised or lowered during operation so that it is always in an optimum working position. This increased range improves productivity and reduces costs.

Ewellix LIFTKIT is a ready-to-install system and includes a lifting column with a robot mounting interface, a controller and a software plug-in for compatible robots so that movements can be programmed directly via the robot controller.

In the LIFTKIT-0S version, the column can be controlled via a standard Ethernet TCP/IP interface. With a set of simple commands, it is possible to connect the LIFTKIT to virtually any type of robot and create a dedicated programme to perform the lifting function.

Benefits

- Extend cobot operating range to increase productivity and save costs

- Plug-and-play solution compatible with virtually any robot brand (according LIFTKIT’s specifications payload, dynamic & static moment)

- No hardware/software upgrades required

- Direct positioning access within the robot control environment (where available)

- Vibration-free movement

- High positioning precision

- Compatible with several palletising software such as Pally

- Compatible with VISUAL COMPONENT software

Features

- Approved positioning axes for Universal Robots, Omron, Techman, FANUC collaborative robots

- Directly recognised by Pally software as lifting solution

- Ready-to-use complete system

- Robust column design for industrial use

- Silent operation

- High stiffness

SLIDEKIT 2.0

Several applications require to cover long distances to perform the operation, like finishing, welding and parts inspection. These repetitive tasks, usually done manually, are time consuming and with low added value for the operators.

By adding a linear module as a dynamic base for the robot, it is possible to extend the handling operating area of the robot, increasing the productivity and output quality. The SLIDEKIT 2.0 provides quick and fast installation, by having a standardized mechanical, electrical and software interface with Universal Robots. In few steps, the system is ready to be used and simply programmed in operation.

Moreover, SLIDEKIT is also available with a general purpose variant, using simple digital I/Os to control the motion, making it compatible with other cobots brands. Cobots combined with the SLIDEKIT 2.0 linear module provide a cost-effective solution to upgrade an existing assembly shop, moving from a manual handled to a fully automatized line.

The 2.0 release of the SLIDEKIT delivers several improvements compared to the former version, like higher system reactivity and stability, lower noise in operation and optimized design for limit switches and re-lubrication points.

Les avantages des LIFKIT

– Augmentation de la plage de fonctionnement d’un cobot

– Compatible avec la gamme Universal Robot UR5 à UR16

– Aucun développement de matériel/logiciel n’est nécessaire

– Accès direct au positionnement dans un environnement contrôlé par UR

– Positionnement rapide pour augmenter la productivité et réduire les coûts

Features

- UR+ certified horizontal positioning axis

- Ready to use complete system solution

- Software plugin (UR Caps) to UR control system included

- High level of positioning precision and repeatability

- Very low noise in operation

- Max dynamic payload 10,9 kN

- Max. linear speed 1 000 mm/s

- Max stroke 3 000 mm

- Plug-and-play for universal robots

January 2023 Linear axis for collaborative robots SLIDEKIT

Obtenir une information, via notre formulaire :

Un expert prendra en charge votre demande afin de répondre au mieux sur ce produit.

Conformément à l’article 43 de la loi ‘Informatique et Libertés’ relative à l’informatique, aux fichiers et aux libertés, vous disposez d’un droit d’accès, de modification, de rectification et de suppression des données qui vous concernent sur simple demande ecrite à commercial@fli-industrie.fr